| Ⅰ.Choose

suitable packing style |

| Some factors will affect the choice

of packing as follow: |

| a.

Style of equipment--------pump, valve, stirrer and so

on |

| b.

Condition of equipment-------new and old status, the gap

between shaft |

|

and stuffing, the shaft running true centred or eccentric |

| c.

The physical characteristics of medium-------gas medium,

liquid medium, |

|

abrasive medium, sticky medium etc |

| d.

The chemical characteristics of medium------acidic medium,

caustic |

|

medium etc |

| e.

The temperature of medium------consider the frictional heat

between the |

|

turning shaft and the packing, the factor of

heat-transmitting properties etc |

|

f.

The

pressure of medium |

| Ⅱ.Confirm

exact packing cross section |

| Ⅲ.Calculating

the exact length of packing ring |

| Ⅳ.Cut

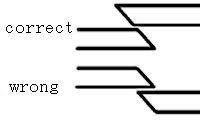

the packing ring exactly |

|

Usually use

45°cut |

| Ⅴ.Inserting

the packing ring into the stuffing box as graph as follows: |

|

| Ⅵ. Press

the packing ring group out, adjust the leakage capacity up

to the |

|

acceptable level. |

|

|